1. Good wear resistance, scratch resistance and anti-slip effect;

2. Slightly rough surface can reduce tire noise;

3. Excellent adhesion and good compatibility with multiple systems;

4. Good weather resistance and chemical resistance;

5. Environmentally friendly and low-odor during construction;

6. Matte or semi-gloss effect, with a soft and elegant luster, avoiding dazzling effects.

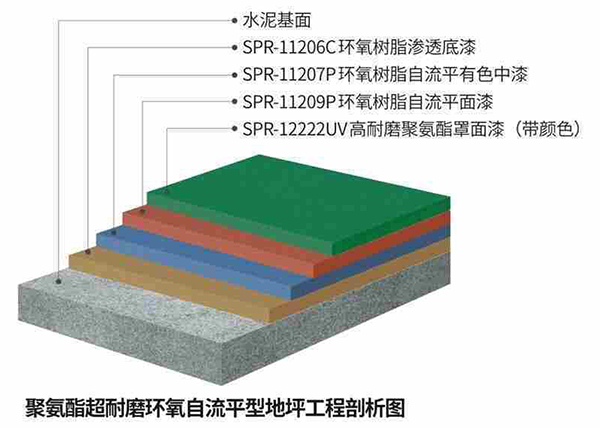

Substrate treatment:

Grind and clean the ground, ensuring that the base material is dry and free of hollowing.

Primer coating:

Enhance penetration and adhesion;

Intermediate coating application:

According to the requirements, design the thickness of the ground and carry out the process of applying mortar and troweling.

Batch coating:

Apply sand or putty to level and ensure the effect of the next process.

Topcoat application:

Apply a coat of epoxy resin self-leveling floor paint with a trowel.

Topcoat application:

Apply the high-wear-resistant polyurethane topcoat by first scraping and then rolling once.

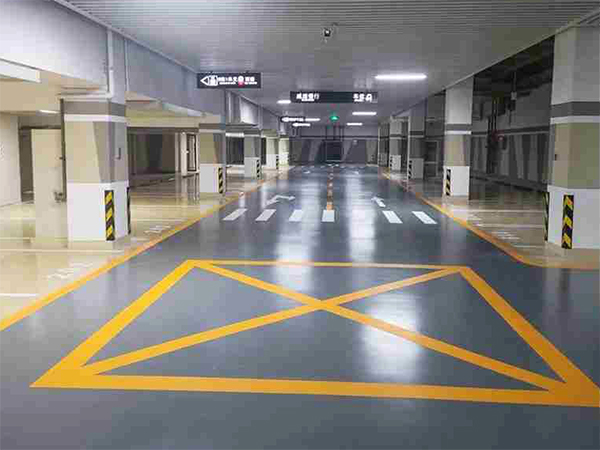

It is mainly applied to the floors of factories, underground garages, commercial and office buildings with anti-slip, wear-resistant and matte requirements. It can be used on ordinary epoxy self-leveling, flat coating systems and ordinary polyurethane topcoats to enhance scratch resistance, wear resistance and anti-slip safety. At the same time, it has the functions of reducing tire noise and reducing reflection. This product is weather-resistant and can be applied in outdoor areas where color retention is required.