1. Waterborne epoxy resin floor coating with anti-static function, two-component supply, low mixing viscosity and easy to stir.

2. Easy to construct, it forms a film after localization, with a bright appearance, strong adhesion, and can bear medium loads.

3. It is cost-effective, wear-resistant, pressure-resistant, and has strong impact resistance. It can effectively eliminate and prevent the generation of static electricity or electromagnetic waves.

4. The constant anti-static function can effectively conduct static electricity into the ground.

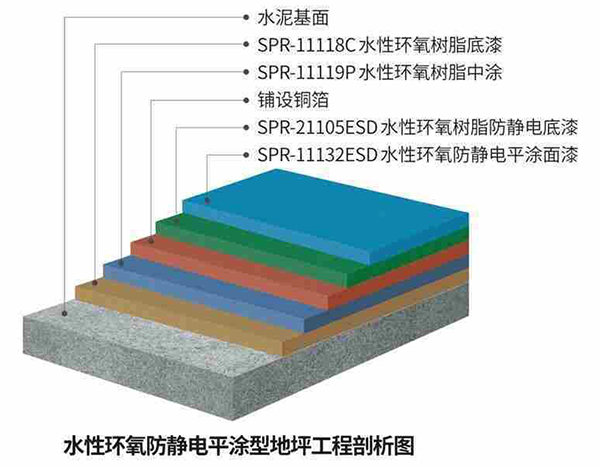

Substrate treatment:

Grind and clean the ground, ensuring that the base material is dry and free of hollowing.

Primer application:

Enhance penetration and adhesion;

Intermediate coating application:

According to the requirements, design the thickness of the ground and carry out the process of applying mortar and troweling.

Lay copper foil:

Laid horizontally and vertically in a crisscross pattern;

Batch coating:

Apply two coats with a conductive coat to ensure the continuity of conductivity.

Topcoat application:

Roller-coated waterborne epoxy resin anti-static topcoat.

It is applicable to places with anti-static requirements such as communication equipment manufacturing plants, precision electronic manufacturing plants, computer rooms, hospital operating rooms, military warehouses, and chemical warehouses.