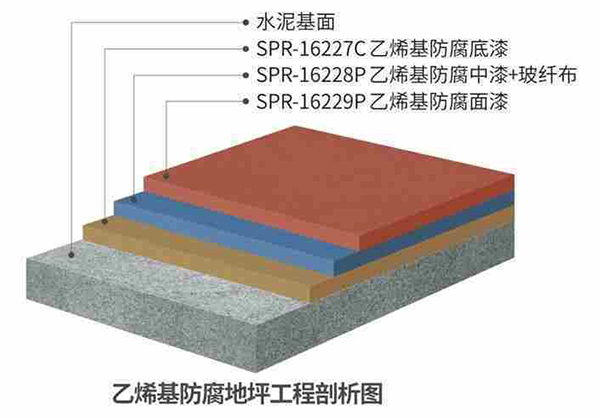

Vinyl heavy-duty anti-corrosion floor is made by using anti-corrosion vinyl resin and glass fiber surface mat as the anti-corrosion layer, vinyl resin material and alkali-free glass fiber cloth as the lifting layer, and attaching a strong and continuous protective fiberglass reinforced plastic anti-corrosion organic chemical safety protective layer on the concrete base surface to prevent the corrosion of the base material by chemical acids, alkalis and salts. According to the application environment, The index values such as the temperature and concentration of substances, as well as the anti-corrosion regulations, adopt different materials and construction techniques.

Plain land treatment:

Do a good job of grinding, dust removal and repair.

Vinyl anti-corrosion primer:

Apply one coat;

Vinyl anti-corrosion intermediate paint (covered with fiberglass cloth):

Lay several lines as per the design;

Vinyl ester batch coating:

Several roads were constructed according to the design.

Vinyl anti-corrosion topcoat:

Apply two coats with a roller or one coat with a trowel.

It is applicable to anti-corrosion of sewage treatment tanks, industrial wastewater treatment tanks, workshop floors, warehouse floors, walls, pre-treatment tanks, oil and fat removal tanks, acid washing and phosphating tanks, acid-base neutralization tanks, sedimentation tanks, electroplating tanks, cleaning tanks, acid and alkali workshops and warehouses, electrophoresis tanks, and anti-corrosion of chemical production and storage. Anti-corrosion of chemical storage areas and tanks, anti-corrosion of neutralization tanks in wastewater treatment plants, anti-corrosion of fermentation tanks and tanks in brewing industries, and anti-corrosion of flammable organic substances storage.