1. It is composed of non-sparking aggregates with a certain particle size distribution, special cement, high-performance conductive powder, other admixtures and additives.

2. Evenly spread it on the surface of the concrete in the initial setting stage. After overall curing, it will form a dense whole with the concrete floor.

3. The super-hardened surface layer is a high-performance wear-resistant floor with high compressive strength, impact resistance, wear resistance, high density and colorability, which can completely avoid the problems of bulging and shrinkage cracks that often occur when using a leveling layer.

4. The surface layer is wear-resistant and not prone to dust. Compressive resistance, impact resistance, and good toughness; It does not produce sparks when hit or rubbed by objects and has excellent anti-static effect.

5. It has A fire resistance rating of Grade A and is an environmentally friendly inorganic floor product.

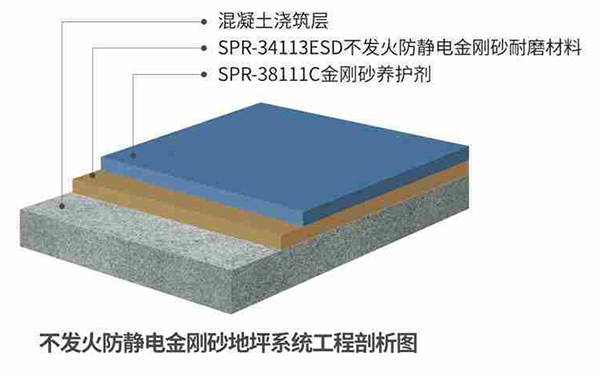

Concrete pouring:

The minimum cement content of the base concrete should be 300kg/m ³, the water-cement ratio should be controlled below 0.55, the on-site collapse of the base concrete should be between 75 and 100mm, and the thickness should be at least 5cm.

Non-sparking anti-static diamond sand surface layer:

First, use a disc mechanical trowel to lift the slurry. Then, evenly spread two-thirds of the SPR-34113ESD non-sparking anti-static diamond sand wear-resistant material to allow the material to fully absorb the moisture in the concrete. Use a trowel to lift the slurry and smooth it out. Finally, evenly spread the remaining one-third of the non-sparking anti-static diamond sand wear-resistant material until it is smooth and finished.

Curing layer:

Spray with SPR-38111C emery curing agent or cure with clean water for 28 days.

It is applicable to the ground of industrial plants, warehouses, supermarkets, heavy-duty machinery factories, machine repair shops, parking lots, goods storage areas, squares, etc.